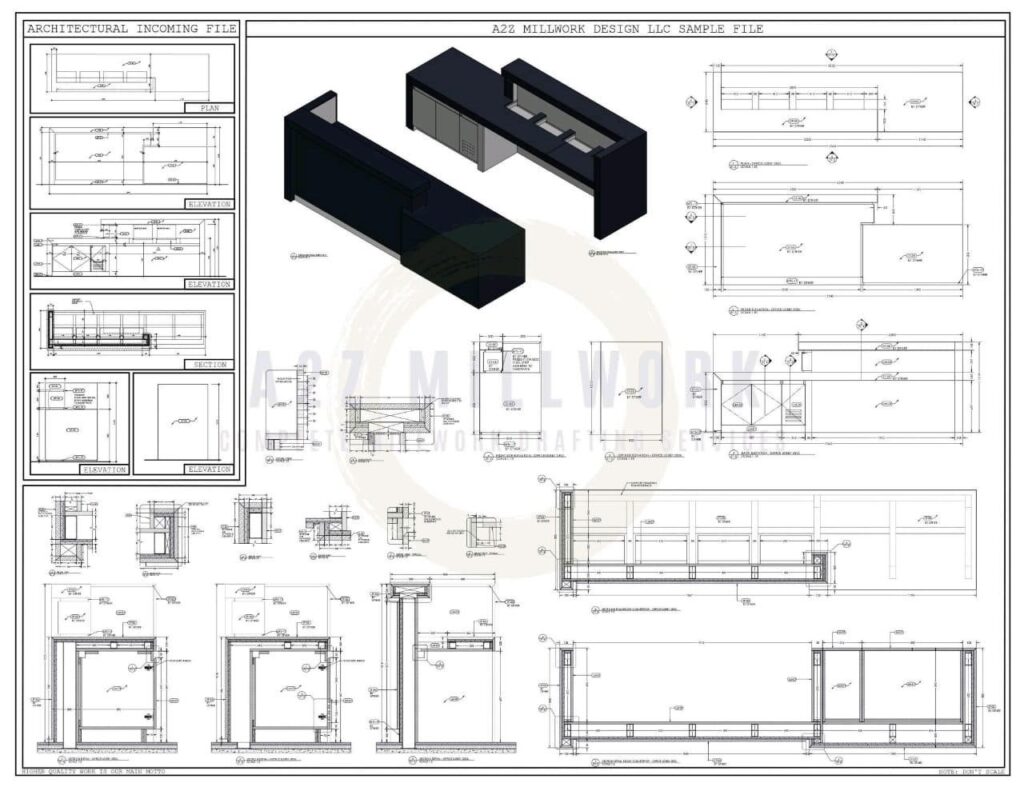

A shop drawing is a bunch of pictures created by the worker for hire, provider, producer, subcontractor, expert, or fabricator. Shop drawings are required for prefabricated components. These include lifts, underlying steel, brackets, pre-projected solid, windows, machines, cupboards, air dealing with units, and millwork.

Shop drawings and 3D modeling help millwork companies and fabricators visualize what they are building. Millwork shop drawings dispose of any misinterpretations and empower precise and convenient creation and establishment of custom cupboards, casework, entryways, and other wood items.

What are all the things included in Millwork Shop Drawings?

Shop drawings explain the stage of the prefabrication procedure after drafting design drawings & statements. They include more information than design and construction drawings and drill down into prefabricated components’ particulars.

A millwork shop drawing typically contains:

- The project title and number

- The date of the initial drawing

- The date of all subsequent revision

- Detailed CAD drawing of the prefabricated component, often shown from different angles.

- Information required to fabricate the element, including physical dimensions, material specifications, manufacturing protocols, and special instructions

- Information is needed to assemble or install the component, such as step by step instructions, a diagram of connections, and a list of helping materials that must be procured & prepared for a successful installation.

- Complete references that describe how the prefabrication design enables the specifications & requirements of the original design and construction documents

- Notes of any changes or any variance from the initial design and construction documents

- Notes of any critical dimensions at the job site must be checked and verified before the component can be manufactured and installed.

- When submitted to a planning group for audit, shop drawings might be joined by tests. The examples address a choice of manufacture materials subject to endorsement in light of the favoured tone, surface, finish, and appearance.

Who creates millwork shop drawings?

Creating shop drawings falls on contractors, subcontractors, manufacturers, material suppliers, or fabricators.

Like many of the technical drawings, shop drawings were once made by hands on a draftsman table. But now professionals digitally craft shop drawings with the aid of CAD software tools such as:-

- Advance Steel

- Advance concrete

- AutoCAD

- AutoCAD Plant 3D

- AutoCAD MEP

- Inventor

- Solidworks

- Solid Edge

The contrast between configuration drawing and shop drawing:-

Design drawings are taken up as the first step of the design phase. They are usually attractive concepts or renderings that represent a client’s ideas and designers’ intent.

Design drawings typically include the following information:

Exterior and Interior elevations.

Interior & exterior three dimensional(3D) renderings.

Site plans.

Floor plan.

Design layouts

Attractive elements, such as colours, textures, and some materials

Connection design

Both shop and design drawings are integral to designing and fabricating various projects, from piping and plate work to the bridge, commercial & industrial developments. Though frequently confused as the same thing, structural steel shop drawings & design drawings each play a clearly different but relatively important role in the construction procedure.

Design drawings are fundamentally utilized in the beginning phase of plan improvement to impart plan thoughts and propositions. In comparison, shop drawings give the details needed by a fabricator during fabrication, assembly, installation, & erection, such as identifying material, weld types, and connections.

What is Shop Drawing Submittals?

Specificities in the shop drawings, material data, samples, and product data in the construction management process are mainly defined as the “submittals“. Submittals prove to be the very crucial stage for the architects and engineers to verify and approve the craftsmanship behind the construction project’s designs and drawings.

The submittal process let project architects & consultants select the color, pattern, & material type after finishing the construction drawing. At this stage, architects and the designers logically determine the material based on the quality and quantity specified in the architectural plans.

Details that have to be involved in shop drawing submittals are as follow:-

1. Annotation:- If there are any changes made in the shop drawings which are different from the actual data given initially, should annotate them for the reference, review, and acceptance of the architects & the engineers of the project. In addition, because of the apparent responsibility an architect and engineer share, should inform them about all the alterations and indications made in the drawings.

2. Fabrication:- Important data required for assembling, like measurements, producing norms, or manufacture guidelines, ought to be engaged with the shop drawing submittals. In addition, the shop drawing should have detailed specifications that can convey the information to the fabricators as the construction documents majorly lack this information.

3. Actual dimensional verification:- The site’s exact dimensions should be verified from surface to surface as the measurements might decrease or augment. The dimensions are involved mainly in the construction documents and drawings, but the original size might change with time due to conditions changing on the site.

4. Comparative information from the architect:- The shop drawing submittals assemble information to compare the drawings and specifications to understand the architects better. Shop drawings generally describe information about the performance, appearance, & prescriptive explanations in the requirements & drawings. While reviewing the shop drawing submittals, the architects continuously refer to the construction documents, specifications, and drawings to thoroughly understand them.

What are the tips for creating a perfect shop drawing?

Following are the tips for creating a perfect shop drawing:-

1. Harness colour:- Color can bring a drawing into life. There are three basic classes of colourization: highly contrasting drawings, drawings with a couple of tones, or a complete shading introduction or delivery. In a black and white or Greyscale display, you can only show lines with numerous thicknesses, in addition to shadow and shade. By selecting only a few colours, you can focus on the strings or individual elements.

2. Take care of details:– Details could mean the literal elements of a building or construction or how a drawing is implemented at multiple scales. With subtleties, you can likewise work through critical thinking or characterize development measures. You can see the evolution of a procedure or drawing and draw attention to numerous points through a work. Elegant detailing is grounded in understanding how people read three-dimensional(3D) ideas through 2D representations.

3. Take a new perspective:- Perspective in the drawing represents an image as the eye would recognize it. Viewpoint is the view from a specific fixed perspective, and verticals and horizontals in the drawing address level and verticals. Lines leading away into the distance emerge to converge at a vanishing point.

4. Embrace new technologies:- It’s important to mention the digital turn & how it has shaped the way we draw and design. The digital revolution in architecture has gone through various stages and phases: folding, nonlinearity, and hypersurfaces, versioning, scripting, information modeling, and Parametricism.

5. See the light:- One of the best techniques for causing your drawings to seem three-dimensional is to think about how light functions. Careful handling of light, shadow, & tone can help define form. Even if you have a single light source or many, you can speedily bring a drawing & sketch to life by knowing how light shapes a building or composition. The shadows within a perspective or advanced view should always be drawn in direct reply to the forms that the light strikes, the angle from which the light is coming, and the light source’s intensity.

6. Use diverse line styles and weights:- Diversified lines can help a client or designer to understand and differentiate the feature of your work or the sketch itself. You can transform lines through weight (thick and thin lines), the movement of your hand, or through how a line is programmed.

7. Don’t forget texture:– When we talk about consistency in drawing, we often refer to a work’s material qualities. You can add different texture types to surfaces through shading and line quality, making them appear smooth, hard, soft, or abrasive.

8. Employ a virtual hierarchy:- Visual scale refers to figuring an element or a series of elements in the drawing. This method is used over a field situation where no particular weight is given to individual components. Visual hierarchy allows you to focus on specific aspects of the drawing & its composition. For example, you can discover consideration utilizing size, shading, line weight, or only giving blank area in a usually packed drawing plane.

Importance of shop drawings in millwork

1. Make sure clear communication between the architect or designer, the client, & the fabricator.

2. Ensure that the fabrication process flows effortlessly, as there is no need to stop fabrication to confirm missing details or dimensions. In this way, shop drawings help to speed up the timeline of construction.

3. Give the fabricator sufficient detail to ensure that steel elements are structurally sound & adhere to all necessary safety, quality, and project standards.

4. Reduce or even eliminate fabrication rework by resolving issues and clashes early on. As a result, pointless use of extra work and materials are evaded.