1) Plan Your Project Before creating your millwork. Determine the dimensions and style of the piece you want to create. You can find inspiration and ideas from interior design websites, magazines, and social media platforms. Next, sketch your design, and make a list of the materials and tools you will need for the project.

2) Create Shop Drawings Next, you must create shop drawings for your millwork. Shop drawings are detailed drawings showing the piece’s dimensions, materials, and construction details. You can create shop drawings yourself or hire a professional to create them for you. Once you have your shop drawings, please review them carefully and revise them before moving on to the next step.

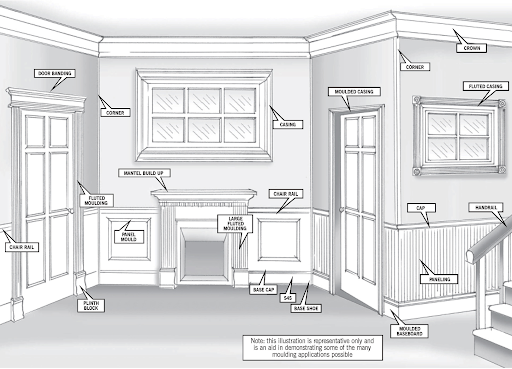

3) Choose Your Materials Selecting suitable materials is essential to create a high-quality millwork piece. Choose durable materials suitable for the type of millwork you are creating. For example, if you are creating a moulding piece, select a high-quality wood species that can be easily shaped and finished. If you are creating cabinetry, choose materials that are resistant to moisture, such as plywood or MDF.

4) You can start cutting and shaping the material to match your shop drawings. Use a saw, a router, and other woodworking tools to cut and shape the materials to the correct size and shape. Take your time, and work carefully to ensure that your pieces are accurate and fit together perfectly.

5) Assemble Your Millwork After you have cut and shaped your materials. Follow the construction details on your shop drawings to ensure you assemble the piece correctly. Use glue, nails, screws, or other fasteners to hold the pieces together. Sand and finish the millwork to give it a smooth, polished look.

6) The final step is to install your millwork piece in your home. Again, follow the installation instructions on your shop drawings carefully to ensure your piece has installed securely and correctly.

Revise and Resubmit Shop Drawing

It is important to note that creating Millwork shop drawings can be complex, and it may require several revisions before the final design is approved. It is especially true when you are drawing and creating the Millwork Pieces themselves. Still, keep going if your initial shop drawings are not up to the mark. You can ask the feedback from the experts of A2z Millwork Design and use it to revise your design. A revised and resubmitted shop drawing can help you create a millwork piece that meets the specifications of your project.Benefits of DIY millwork

DIY millwork has gained significant popularity in recent years as more homeowners seek to take on home improvement projects and personalize their living spaces. Millwork is the term used to describe various products made from milled lumber, including moldings, trim, and other decorative accents. Here are some of the benefits of DIY millwork.Save Money:

Firstly, DIY millwork can save homeowners money. Purchasing pre-made millwork from a home improvement store can be expensive, especially if the homeowner has a lot of trim or molding to install. Homeowners can save a significant amount of money on materials by purchasing raw lumber and milling it themselves. Additionally, homeowners can save on installation costs by doing the work themselves.Greater Customization:

Secondly, DIY millwork allows for greater customization. When purchasing pre-made millwork, homeowners are limited to the options available at their local home improvement store. By milling the lumber, homeowners can create unique, custom pieces that perfectly fit their space and design aesthetic. It is especially beneficial for older homes that have unusual or non-standard dimensions.Fun and Rewarding:

DIY millwork can be a fun and rewarding DIY project. Many homeowners enjoy the satisfaction of completing a project themselves, and millwork can be an excellent option for those looking for a challenging but manageable task. Additionally, millwork can add significant value to a home, so homeowners can feel proud of their work while increasing their property’s value.Learn New Skills:

DIY millwork can be a great way to learn new skills. Milling lumber requires precision and attention to detail, and homeowners who take on this project will likely learn valuable skills that will be applied to other DIY projects. Additionally, by doing the work themselves, homeowners can gain a deeper understanding of their home’s construction and design, which can be helpful in the event of future maintenance or repair needs. DIY millwork can be a cost-effective, customizable, fun, and skill-building project for homeowners looking to add value and personalization to their homes.Disadvantages of DIY Millwork

First and foremost, DIY millwork requires significant skill and expertise to execute correctly. Unlike other DIY home improvement projects that could be learned through trial and error, millwork requires a deep understanding of woodworking techniques and tools. Without this knowledge, it is all too easy to make mistakes that can compromise the structural integrity and aesthetics of the finished product. In addition, the unfair practice could lead to costly repairs or replacement, undoing any initial cost savings.

DIY millwork can be time-consuming, requiring a considerable investment of both time and effort. The task can be particularly challenging for those with busy schedules or limited physical abilities, as the process of cutting, sanding, and installing custom wooden features can be quite physically demanding.

Another major disadvantage of DIY millwork is the potential safety risks involved. Woodworking tools, such as saws, drills, and sanders, can be dangerous when not used properly. Improper use of these tools can result in serious injury, making it crucial to have a strong understanding of safety protocols before embarking on a millwork project.

Finally, DIY millwork can also be quite expensive considering all factors. While the initial cost savings of crafting and installing wooden features oneself may seem appealing, the cost of purchasing high-quality tools and materials can quickly add up. Additionally, mistakes or accidents can result in added expenses for repairs or replacements, further increasing the project’s overall cost.